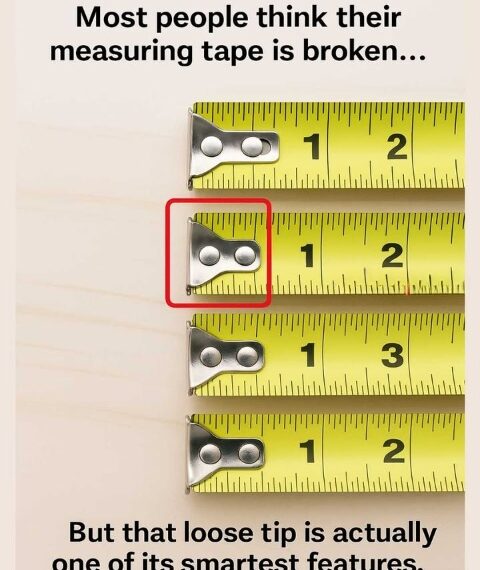

➤ When you measure an inside edge:

You press the tip inward against the wall or object. It moves in just enough to subtract its thickness, again keeping the measurement accurate.

Without this movement, your measurements would be consistently off by the thickness of the metal end—often enough to ruin a DIY or construction project.

🧠 Why Most People Don’t Know This

It’s easy to mistake the movement for wear or damage. After all, most tools are designed to be sturdy and firm. But this particular piece of engineering is an example of functional flexibility—it’s loose on purpose so it can adapt to different measuring scenarios.

🔍 A Fun Fact from the Pros

Many professional carpenters and contractors know this trick well. In fact, some higher-end tapes are even labeled with “True Zero Hook,” emphasizing this floating mechanism as a precision feature.

According to the National Institute of Standards and Technology (NIST), properly calibrated tape measures rely on this hook movement to maintain accuracy. In other words, if your tape’s tip didn’t move, your measurements wouldn’t be precise!

🧰 Bonus Tip: The Other Features of a Tape Measure Hook

The hook doesn’t just move—it also includes other smart features:

- Small slot/hole in the hook: Perfect for catching onto a nail or screw head for solo measurements.

- Serrated bottom edge: Can scribe a line when no pencil is handy.

- Rivets: These allow the movement while also keeping it securely attached.

✅ In Summary

That “loose” tip on your measuring tape is actually a built-in calibration system. It’s there to:

- Adjust for hook thickness

- Ensure inside and outside measurements are accurate

- Improve precision in both DIY and professional projects

So next time someone thinks their tape is broken, you’ll know the truth—and can impress them with your newfound knowledge! 🧠📐